Balance Tank CIP Skid

SYNCS provide custom-designed clean-in-place or CIP systems for leading manufacturers in the FMCG, food, dairy, beverage, and pharmaceutical/biotech industries. To better meet your needs, our cleaning systems are custom-designed and fabricated based on your unique requirements.

We design and manufacture sanitary process cleaning equipment including Clean-in-Place (CIP) Systems and Clean-Out of-Place (COP) Systems. By providing you with an easy-to-use, efficient and effective cleaning system, we know that allows you to concentrate on the production side of your operation. All systems are designed and custom built to best address your needs.

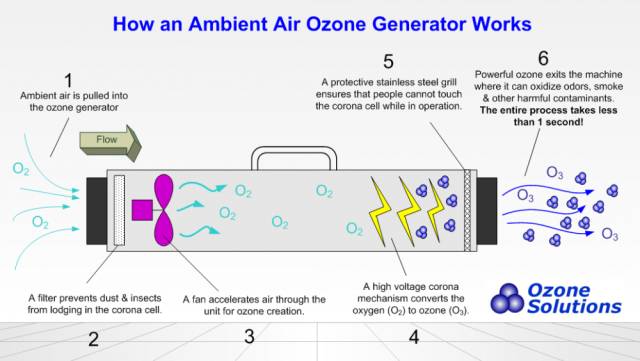

CIP Skid or Clean-In-Place (CIP) Systems

CIP Systems offer a safer, more consistent method of plant sanitation. Our Processing Engineers will appropriately design, size, and program a customised CIP Skid that ensures effective cleaning while also minimising cycle time, lowering chemical usage, and reducing water and utility consumption. Your CIP System will meet all industry standards including 3A, and EHEDGE requirements. The CIP system can be also supplied in single balance tank CIP skid or multiple tanks CIP skid for multiple circles of sanitation.

Benefits of a CIP System:

• Less time and fully automated control with minimum operator involvement.

• Environmental and cost improvements achieved through the effective use and reuse of water, cleaning chemicals and boiler condensation.

• Enhanced operational hygiene can improve product quality, recovery and purity.